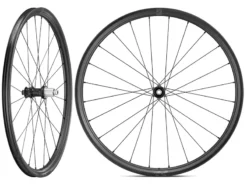

Fulcrum Rapid Red Carbon Disc Brake Gravel Bike Wheelset – Black

£399.00 Original price was: £399.00.£98.99Current price is: £98.99.

- Safe and Secure Shopping

- Service with a smile, always online.

- Protect Your Wallet with Safe Payments

- Enjoy top quality items for less

Fulcrum Rapid Red Carbon: discover new horizons fast.

The Rapid Red family of wheels now boasts a set of wheels dedicated to those who want to discover new terrains and new trails, with a touch of extra speed. Fulcrum has applied the technological know-how from our top of the range wheels to develop the reactive, light and reliable Fulcrum Rapid Red Carbon, for gravel (and for whatever gravel means to you).

Lightness and reactivity are guaranteed by the S-Shape asymmetrical profile carbon rim. This technology improves the balance between the tension of the spokes. The optimised balance ensures long term performance levels. Moreover, the unique shape of the rim profile increases stiffness by 2.5% compared to a traditional U-shaped profile.

To achieve maximum performance with tubeless tyres, the Rapid Red Carbon feature a tubeless-specific non-drilled bridge: 2-Way Fit. The non-drilled bridge has a C-Lux Finish, a mirror-like finish that makes it easier to install the tyre. The wheel assembly is completed with Fulcrum’s patented Mo-Mag technology, which uses a simple and ingenious solution to seat the nipple on the rim hole with a magnet.

The rim has a 30 mm high profile with a mini-hook system that extends its compatibility with a wider range of pressures (the only limit is the one given by the tyre). Moreover, Fulcrum’s dimensional precision guarantees greater safety against the tyre rolling off the rim at low pressures, thanks to the larger support surface available with the wider inner rim width of 25 mm.

And as you’ve come to expect from #fulcrumfast, we have also employed functional solutions that marry aesthetics and performance. At a glance, you will immediately notice the new Direct Inmold Matt Finish (DIMF)

The Fulcrum Rapid Red Carbon are the perfect solution for demanding riders looking for a top of range product with “made in Europe” technology.

Technologies:

2-WAY FIT™

2-Way Fit™ profile for tubeless and clincher.

Tubeless technology was first used by the auto industry, then by motorcycles and now has reached the cycling industry. After its debut with mountain bikes the moment has come to “put it on the road”, and that’s what we propose to do.

We have developed our 2-Way Fit™ technology to ensure the perfect compatibility of our tubeless rims with normal clincher types and tubes. 2-Way Fit™road bike wheels are perfectly multipurpose for tackling every situation. Thanks to a special impression in the valve area, the tubes are fitted with maximum precision while keeping the tube perfectly stable inside the tyre. Housing the valve for tubeless tyres is also risk-free, with the unquestionable advantage that there are never any air infiltrations caused by non-ideal positioning when fitting.

RDB™ RIM DYNAMIC BALANCE

The concept is simple and elegant: balance the weight of the gasket, with an item of similar weight placed on the exact opposite side.

MOMAG™

What is MoMag™?

A magnet and lots of ingenuity. This was what led to the patent for the well-tested “Mounting Magnet” system, or MoMag™. The nipples, once inserted inside the rim via the valve hole, are “guided” to the point of connection with the spoke by means of the magnet. This simple but ingenious system makes it possible to have wheels without holes on the upper bridge, but with spokes tensioned by traditional nipples!

No holes on the rim mean that the rim is uniform at every point, free from stress points or zones of weakness and, for the clincher profiles no rim tape is required, to the benefit of weight reduction. The advantages are immediately clear: greater rim lifetime, greater resistance to fatigue, the possibility to give the spokes greater tension, and greater stiffness which, in terms of performance, mean greater reactivity and acceleration.

F.I.C. FULCRUM IDENTIFICATION CARD – 100% HANDMADE QUALITY

Right from its inception, Fulcrum® has been marked by the feature that continues to this day: is to design, prototype and industrialise all the wheels characterised by the red “F”. Indeed these take shape inside of the R&D, the leading-edge department that represents the beating heart of the Italian company.

Every single component of the wheel, the materials chosen and the technologies applied are the tangible result of the effort that Fulcrum® makes every day to give you maximum performance and reliability.

TRACEABILITY

A guarantee of quality

The keyword for our products is traceable.

If you find a little label attached to any Fulcrum® product, do not remove it. It will provide you with a guarantee in case of an ascertained defectiveness of a production batch, and so the component needed or wheel will be traceable. All this because, devoted to its mission, Fulcrum® demands absolute perfection and safety for its customers.

AFS AXLE SYSTEM™

The Axial Fixing System™ is the solution developed by Fulcrum® to fix the disc brake to the hub. The constraint granted by the butt area of the release mechanism, greater than in familiar standard ones, makes it possible to obtain greater structural rigidity and therefore more precise and powerful braking.

RIM FULL-CARBON TECHNOLOGY

Full carbon Fulcrum® rims are built using combinations, developed in the laboratory, of different types of fibre, including UD and the famous 90-degree 3K of models at the top of our range. To build them we developed a special HTG (high transition grade) resin, whose glass transition point is at a higher temperature than any other fibre used in the bicycle industry. This gives incomparable performance when braking.

UNDRILLED RIM BED

No holes on the bridge connector mean that the rim is uniform at every point, free from critical areas subject to stress. The advantages are immediately clear: less weight, longer lasting rims, greater resistance to fatigue, the possibility of giving the spokes more tension and more stiffness which, in terms of performance, means improved responsiveness and acceleration.

CUP & CONE

The cup-and-cone bearing differs from the classic cartridge bearing because it works in perfect alignment with the forces involved, weight and thrust from the frame, as the bearings run in a race positioned directly opposing these forces.

| Choose Options | Campagnolo N3W, Black, Shimano HG11, Black, SRAM XDR, Black |

|---|

Be the first to review “Fulcrum Rapid Red Carbon Disc Brake Gravel Bike Wheelset – Black” Cancel reply

Related products

Wheels, Tyres & Tubes

Tubeless Kits, Sealants & Spares

Wheels, Tyres & Tubes

Specialized Hillbilly Grid Trail 2Bliss T9 27.5 X 2.4 MTB Tyre

Wheels, Tyres & Tubes

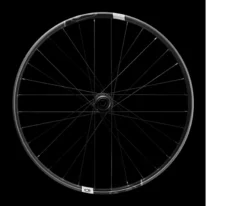

Crankbrothers Crank Brothers Synthesis Carbon 29er Boost E-MTB Wheelset

Wheels, Tyres & Tubes

Reviews

There are no reviews yet.